Revolutionizing Surface Treatments: The Undeniable Impact of Chem-Film on Aerospace Metals

Surface treatments are pivotal in enhancing aerospace metals’ durability and overall performance. Chem-film has emerged as a revolutionary option in this regard, altering how people approach metal protection. Its undeniable impact stems from its capacity to establish a protective layer on metal surfaces, reducing corrosion and increasing resistance.

Over the years, aerospace surface treatments have witnessed a dynamic evolution marked by various emerging trends and cutting-edge technologies. This article will explore chem-film and some of the most notable advancements in the sector.

Working Principles and Benefits of Chem-Film

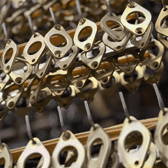

Chem-film, also called chromate conversion or Alodine coating, is a chemical process widely employed in the aerospace and manufacturing industries. Its primary objective is to create a thin, corrosion-resistant layer on a metal substrate. This layer is a barrier that shields the metal from environmental factors such as moisture, salt, and other corrosive elements.

One of chem-film’s key components is hexavalent chromium, which reacts with the surface to form a protective film. This provides corrosion resistance and enhances the adhesion of subsequent coatings, making it a crucial step in the surface treatment process. Depending on the specific formulation used, the layer can appear in various colors, such as gold or iridescent.

Here are the most significant benefits of this coating technology:

- Improved paint adhesion

- Enhanced electrical conductivity

- Increased longevity of metal components

- Compatibility with various metal substrates

- Versatility in coating thickness

- Potential for self-healing properties

Despite its effectiveness, there is a growing emphasis on developing alternative options due to concerns associated with hexavalent chromium. Researchers are investigating trivalent chromium and other eco-friendly formulations to maintain the benefits of this technology. They aim to address environmental considerations in modern surface treatment practices.

Notable Surface Treatments Advancements in the Aerospace Industry

The following advancements collectively contribute to the ongoing improvement of aerospace surface treatments:

Advanced Surface Pre-Treatments

Pre-treatment before the application of coatings has evolved to enhance the bonding between the metal substrate and protective layers. Innovations in surface preparation technologies contribute to improved adhesion, ensuring that they adhere uniformly to the surface.

Ceramic Coatings for Thermal Protection

With the increasing demand for high-performance aircraft, ceramic coatings have gained prominence for their thermal protection properties. They are designed to withstand extreme temperatures, making them crucial for components exposed to intense heat during flight.

Environmentally Friendly Coatings

As sustainability becomes a focal point across industries, aerospace surface treatments have evolved with the development of environmentally friendly coatings. For example, water-based formulations and other eco-conscious alternatives are gaining traction.

Nanotechnology Integration

Nanomaterials offer unique properties, such as high surface area and reactivity, contributing to improved corrosion resistance and enhanced durability of aerospace components. Nanocomposites, in particular, show promise in providing superior protection against environmental factors.

Plasma and Ion Beam Technologies

These methods allow for tailored surface modifications, optimizing adhesion, wear resistance, and other critical properties. The ability to precisely engineer surface characteristics also contributes to aerospace components’ overall efficiency and longevity.

Smart Coatings and Sensors

Smart coatings actively monitor the structural health of aircraft components, providing real-time data on potential issues. This enhances maintenance efficiency and improves overall safety and reliability in aerospace systems.

Choose New Method Plating for High-Quality Metal Finishing Services

At New Method Plating, we deliver top-notch cadmium and zinc plating services! Our team ensures rapid turnaround times without compromising the precision and quality of our electroplating processes. We also prioritize customer satisfaction and strive to exceed expectations, making New Method Plating your trusted partner for superior surface treatment solutions.

Contact us today to learn more about our metal finishing solutions! You can also request a quote now.