Clear Zinc Plating

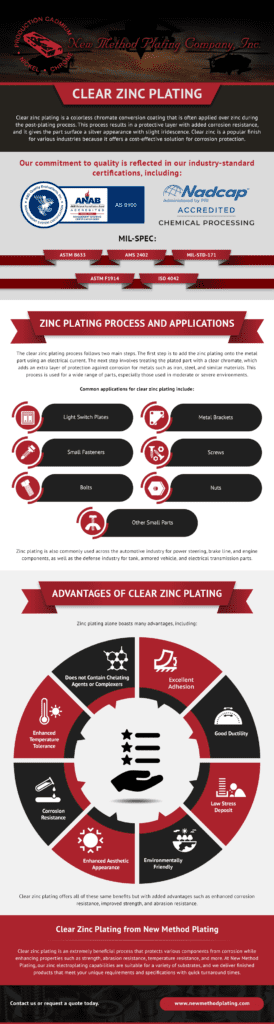

Clear zinc plating is a colorless chromate conversion coating that is often applied over zinc during the post-plating process. This process results in a protective layer with added corrosion resistance, and it gives the part surface a silver appearance with slight iridescence. Clear zinc is a popular finish for various industries because it offers a cost-effective solution for corrosion protection.

At New Method Plating, we are an industry leader in providing high-quality zinc electroplating services. Founded in 1931, we offer a high level of expertise and maintain all crucial industry standard certifications, including

- ISO 9001:2015

- AS9100

- Nadcap AS7108

- Mil-Specs: ASTM B633, AMS 2402, MIL-STD-171, ASTM F1914, ISO 4042

In this page, we will discuss the clear zinc plating process as well as its common applications and key advantages.

Zinc Plating Process and Applications

The clear zinc plating process follows two main steps. The first step is to add the zinc plating onto the metal part using an electrical current. The next step involves treating the plated part with a clear chromate, which adds an extra layer of protection against corrosion for metals such as iron, steel, and similar materials. This process is used for a wide range of parts, especially those used in moderate or severe environments. Common applications for clear zinc plating include:

- Light switch plates

- Metal brackets

- Small fasteners

- Screws

- Bolts

- Nuts

- Other small parts

Zinc plating is also commonly used across the automotive industry for power steering, brake line, and engine components, as well as the defense industry for tank, armored vehicle, and electrical transmission parts.

Advantages of Clear Zinc Plating

Zinc plating alone boasts many advantages, including:

- Excellent adhesion

- Good ductility

- Low stress deposit

- Environmentally friendly

- Enhanced aesthetic appearance

- Corrosion resistance

- Enhanced temperature tolerance

- Does not contain chelating agents or complexers

- And more

Clear zinc plating offers all of these same benefits but with added advantages such as enhanced corrosion resistance, improved strength, and abrasion resistance. This process is also popular across a wide range of industries because it is widely available and provides a cost-effective method for improving part protection.

Clear Zinc Plating from New Method Plating

Clear zinc plating is an extremely beneficial process that protects various components from corrosion while enhancing properties such as strength, abrasion

resistance, temperature resistance, and more. This ensures long-lasting, durable parts capable of withstanding a wide range of operating conditions ranging from high heat and humidity to chemical exposure and other harsh environments. This makes clear zinc plating a popular choice for industries such as military, automotive, construction, manufacturing, and more.

Since 1931, New Method Plating has been providing superior zinc electroplating services. With decades of experience, we offer high levels of expertise and a strong dedication to quality. We maintain all crucial industry-standard certifications, including:

- AS9100

- ISO 9001:2015

- Mil-Specs: ASTM B633, AMS 2402, MIL-STD-171, ASTM F1914, ISO 4042

- Nadcap AS7108

At New Method Plating, our zinc electroplating capabilities are suitable for a variety of substrates, and we deliver finished products that meet your unique requirements and specifications with quick turnaround times.

For more information about our clear zinc plating capabilities and other electroplating services, contact our experts today. You can also request a quote to get started on your custom electroplating solution.