Chem Film Coatings

Since 1931, New Method Plating has been a pioneer in the coating and plating business. As a family-owned and operated business, we are committed to providing our customers with quality finished metal products using the latest technology, highly experienced technicians, and rigorous quality assurance processes. Our specialty electroplating and metal finishing services include everything from cadmium, nickel, and zinc plating to protective chem film surface coatings.

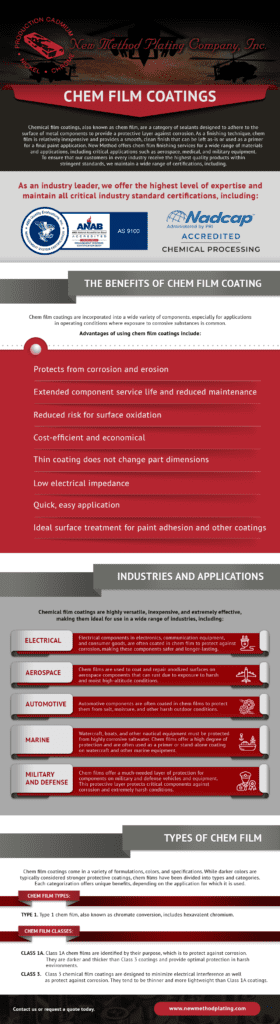

Chemical film coatings, also known as chem film, are a category of sealants designed to adhere to the surface of metal components to provide a protective layer against corrosion. As a finishing technique, chem film is relatively inexpensive and provides a smooth, clean finish that can be left as-is or used as a primer for a final paint application. New Method offers chem film finishing services for a wide range of materials and applications, including critical applications such as aerospace, medical, and military equipment. To ensure that our customers in every industry receive the highest quality products within stringent standards, we maintain a wide range of certifications, including.

- ISO 9001:2008

- AS9100

- Nadcap AS7108

- Mil-Specs:

- MIL-DTL-5541

The Benefits of Chem Film Coating

Chem film coatings are incorporated into a wide variety of components, especially for applications in operating conditions where exposure to corrosive substances is common.

Advantages of using chem film coatings include:

- Protects from corrosion and erosion

- Extended component service life and reduced maintenance

- Reduced risk for surface oxidation

- Cost-efficient and economical

- Thin coating does not change part dimensions

- Low electrical impedance

- Quick, easy application

- Ideal surface treatment for paint adhesion and other coatings

Industries and Applications

Chemical film coatings are highly versatile, inexpensive, and extremely effective, making them ideal for use in a wide range of industries, including:

- Electrical.Electrical components in electronics, communication equipment, and consumer goods, are often coated in chem film to protect against corrosion, making these components safer and longer-lasting.

- Aerospace.Chem films are used to coat and repair anodized surfaces on aerospace components that can rust due to exposure to harsh and moist high-altitude conditions.

- Automotive.Automotive components are often coated in chem films to protect them from salt, moisture, and other harsh outdoor conditions.

- Marine.Watercraft, boats, and other nautical equipment must be protected from highly corrosive saltwater. Chem films offer a high degree of protection and are often used as a primer or stand-alone coating on watercraft and other marine equipment.

- Military and Defense.Chem films offer a much-needed layer of protection for components on military and defense vehicles and equipment. This protective layer protects critical components against corrosion and extremely harsh conditions.

Types Of Chem Film

Chem film coatings come in a variety of formulations, colors, and specifications. While darker colors are typically considered stronger protective coatings, chem films have been divided into types and categories. Each categorization offers unique benefits, depending on the application for which it is used.

Chem Film Types:

- Type 1.Type 1 chem film, also known as chromate conversion, includes hexavalent chromium.

Chem Film Classes:

- Class 1A.Class 1A chem films are identified by their purpose, which is to protect against corrosion. They are darker and thicker than Class 3 coatings and provide optimal protection in harsh environments.

- Class 3. Class 3 chemical film coatings are designed to minimize electrical interference as well as protect against corrosion. They tend to be thinner and more lightweight than Class 1A coatings.

Reliable Chem Film Coatings From New Method Plating

At New Method, we pride ourselves on providing our customers with the highest quality chemical film coatings for nearly any application. We understand that every industry has different requirements, which is why we maintain a wide variety of industry certifications. Whether you require a corrosion-resistant primer for off-road military vehicles or a thin coating for electrical components, we have the knowledge, equipment, and skill to provide you with superior coating services quickly and within your budget.

To learn more about our selection of chem film coatings and plating services, contact our experts today.