Vapor Degreasing

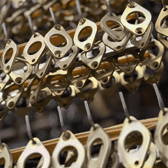

Vapor degreasing is a highly effective cleaning method that uses solvent vapors to remove oils, greases, cutting fluids, and contaminants from metal surfaces. It’s particularly beneficial for parts with intricate shapes and small crevices that are difficult to clean.

New Method Plating Co., Inc. is an electroplating and metal finishing provider that offers vapor degreasing services for cleaning metal parts. Compared with more traditional solvent-based cleaning methods, our methods lend to superior cleaning performance, improved part quality, and a more efficient cleaning process. Read on to learn more.

Benefits of Vapor Degreasing

Vapor degreasing is widely used for cleaning metal parts. The benefits our customers enjoy through our vapor cleaning services include:

- Thorough cleaning. Unlike immersion cleaning, vapor can reach into tight crevices and small holes to provide a more thorough cleaning without damaging the part’s surface.

- Speed and efficiency. The solvent vapors rapidly condense upon contact with metal surfaces to dissolve contaminants faster than other cleaning methods.

- Improved part quality. Our process is gentle on metal parts, reducing the likelihood of damage such as corrosion or distortion that can occur with harsher cleaning methods.

- Reduced solvent usage. Compared to immersion cleaning, which requires a large volume of solvent for each cleaning cycle, our process uses less solvent, reducing operating costs and minimizing environmental impact.

- Enhanced safety. Our vapor degreasing systems include advanced safety features and proper ventilation to keep workers safe throughout the process.

Applications of Vapor Degreasing

Our vapor degreasing services are used in a number of industries that require greater precision and cleanliness. Key applications include:

- Aerospace. Vapor degreasing is employed in the aerospace industry to clean critical components such as engine parts, turbine blades, and landing gear.

- Automotive. In automotive manufacturing, vapor degreasing cleans components such as engine blocks, transmission parts, and brake systems.

- Manufacturing. Precision-machined parts, including those used in electronics and medical devices, often require the high level of cleanliness that vapor degreasing provides.

- Military. The military uses vapor degreasing to clean various pieces of equipment and hardware, including firearms, missile parts, and communication devices.

Vapor Degreasing Process

The vapor degreasing process is a multi-step procedure that effectively removes contaminants from metal parts. Here’s how the process works:

- Pre-cleaning. We pre-clean parts to remove large debris or loose contaminants. This step ensures that the parts are ready for the detailed cleaning process.

- Vapor phase cleaning. The metal parts are then placed in the vapor degreaser chamber, where the heated solvent vaporizes and then condenses on the cooler metal surfaces to dissolve oils, greases, and other contaminants.

- Condensation phase cleaning. During this phase, the solvent continues to dissolve remaining contaminants as it condenses on the metal parts. This multi-phase cleaning process ensures maximum contaminant removal.

- Rinsing. After completing the cleaning stage, the parts require rinsing with a clean solvent to ensure that no residual contaminants remain on the surface.

- Drying. Finally, the cleaned parts are dried either by air drying or using forced air. This final step ensures that the parts are moisture-free before further processing.

Vapor Degreasing From New Method Plating

At New Method Plating, we specialize in high-quality vapor degreasing services to meet the specific needs of your industry. Whether you are in defense, automotive, or manufacturing, our advanced vapor degreasing process guarantees thorough cleaning, improved part quality, and increased operational efficiency. It is safe and precise, making it suitable for a range of parts and materials.

If you are looking to optimize your metal cleaning processes, contact us today for more information or to request a quote.