Cadmium vs. Zinc Plating: What You Need To Know

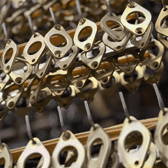

Metal plating is a technique in which a metal layer is electrochemically deposited onto the surface of the substrate (base material). This method is utilized in various sectors to enhance materials’ durability, aesthetics, and corrosion resistance.

Cadmium and zinc are two of the most popular metals used for plating, and each has distinct benefits that make them suited for particular applications. This article will explain cadmium and zinc plating, including their advantages and particular applications.

Cadmium vs. Zinc Plating: How Do They Work?

Cadmium plating is an electroplating process that involves depositing a thin layer of cadmium onto a metal surface. Depending on the object being plated, it can be performed in various techniques, such as a barrel, rack, and continuous plating. In addition, it is frequently employed in aeronautical and military applications.

On the other hand, zinc plating is also an electroplating process utilizing a thin layer of zinc. It can also be performed using a barrel, rack, and continuous plating and customized with different types of zinc coatings. These include yellow, black, clear, or olive drab. Furthermore, it is often utilized in the automotive and construction industries.

Typically, both the cadmium and zinc plating procedures consist of the following steps:

- Before plating, it is crucial to properly clean the metal surface of any impurities like dirt, grease, rust, and other contaminants. This can be accomplished through degreasing and acid-cleaning procedures.

- The metal surface is prepared to receive the plating by activating it with an acidic solution, which enhances its receptivity to the plating material.

- A direct current is applied to the metal object while it is submerged in an electrolytic bath containing a salt solution. This causes ions to be attracted to the metal surface, where they are deposited as a thin coating.

- Once the plating is complete, the object is rinsed to eliminate any remaining reagent. It may also be subjected to additional processes, such as chromate conversion or baking, to improve its adhesion and resistance to corrosion.

Benefits of Cadmium Plating

Due to its unique features, cadmium plating is a versatile procedure widely employed in various sectors. It specifically provides the following advantages:

Excellent Corrosion Resistance

Cadmium plating is widely known for its exceptional corrosion resistance, especially in harsh conditions. The distinctive chemical characteristics of cadmium make it exceptionally resistant to rust, oxidation, and other types of corrosion.

High Conductivity

Cadmium is a highly conductive, low-resistance metal that facilitates the optimal flow of electricity. This makes cadmium plating an excellent option for electrical applications requiring high conductivity, including couplings, ports, and other electronic components.

High Ductility

The ductility of cadmium plating enhances its flexibility and deformability without losing its protective qualities. This feature allows it to be used for aerospace and military applications in which the object is subjected to extreme stress or mechanical strain.

Uniform Coating

Cadmium plating provides an extremely uniform coating, ensuring the whole metal surface is evenly coated. This advantage is crucial when the plating is designed to provide a barrier against corrosion and other damage. Additionally, it assures that the end product has a uniform appearance.

Benefits of Zinc Plating

Zinc plating is extensively utilized in various industries due to the following benefits:

Good Corrosion Resistance

The natural tendency of zinc to produce a protective layer on its surface helps to prevent rust and other forms of corrosion. Consequently, zinc plating is recommended for applications not exposed to seawater or other chemicals since it provides better corrosion protection in dry conditions.

Affordability

Because zinc is a relatively inexpensive metal, the plating technique is more cost-effective than other plating methods. Zinc plating also consumes less energy than other processes, decreasing project costs.

Non-Toxicity

Zinc is a non-toxic metal, which makes it preferable to other elements in many applications. Thus, it is commonly employed in the food and beverage industries.

New Method Plating: The Leading Provider of Precision Electroplating!

At New Method Plating, we have vast experience providing cadmium and zinc plating services, assuring our clients of quick turnaround times and exceptional results! We are strongly committed to high standards and pride ourselves in our craftsmanship. These values enable us to give our loyal customers electroplating solutions of the highest caliber.

Contact us today to learn more about our services and solutions, or request a quote!