The Ultimate Guide to Aerospace Metal Finishing

Comments Off on The Ultimate Guide to Aerospace Metal FinishingIn aerospace applications, materials and parts are manufactured to strict requirements and specifications so they are durable and reliable. Metal finishing is an important aspect of manufacturing because it prepares materials for operating conditions, wear and tear, and functional requirements while in use.

At New Method Plating, we are a NADCAP-accredited and ISO 9001:2015- and AS 9100-certified company that specializes in precision electroplating with cadmium, nickel, zinc, chrome, and copper. Learn more about metal finishing for aerospace components, the plating techniques and materials we use, and the importance of NADCAP and AS 9001 compliance.

The Significance of Aerospace Plating

Plating serves multiple functions from enhancing corrosion resistance or conductivity to providing wear protection, and more. Unlike many standard industrial applications, aerospace component finishing requires higher levels of precision as well as compliance with specifications for performance and safety. These include:

- Corrosion protection: Including in harsh environments (e.g., moisture, chemicals, and temperature extremes).

- Adhesion and conductivity: For electrical and avionics systems.

- Improved compatibility: Especially with certain base metals and composite materials.

- Thickness tolerances: For safety and performance in mission-critical parts.

- Traceability and quality controls: To meet strict standards for OEMs and government contractors.

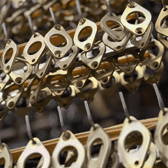

Cadmium Plating for Aerospace Components

Cadmium plating is common in aerospace manufacturing. This material provides sacrificial corrosion protection and strong lubricity, making it ideal for high-torque threaded parts and fasteners. It also prevents galvanic corrosion in dissimilar metal assemblies to extend component life.

For any of the following design requirements, cadmium plating is often the ideal solution:

- Low electrical contact resistance.

- Effective protection against thread seizing.

- Excellent corrosion resistance in marine and high-humidity conditions.

- Good solderability and bonding characteristics.

Chem Film Applications in Aerospace

Chem film, or chromate conversion coating, is used to protect aluminum components. By creating a passive film on the surface, chem films help resist corrosion while preserving electrical conductivity and paint adhesion. This is especially important on aircraft skin panels and electronic housings.

A quality chem film also facilitates:

- Conductive finish for electronic enclosures.

- Corrosion protection on aluminum alloys.

- Primer base for painted surfaces.

- Repairable surfaces for in-service aircraft maintenance.

Nickel Plating in Aerospace Manufacturing

For components requiring high wear resistance and dimensional accuracy, nickel plating provides a hard, uniform coating. Aerospace engineers often specify electroless nickel for turbine blades, actuators, and hydraulic system components.

Nickel plating offers an excellent balance of precision, durability, and these additional factors:

- Uniform deposition on complex geometries.

- High hardness and abrasion resistance.

- Good chemical resistance in hydraulic systems.

- Compatible with various base metals, including steel and aluminum.

Zinc Plating for Aerospace Parts

While not as widespread as cadmium plating, zinc plating is often found in non-flight-critical aerospace parts. Zinc protects steel substrates from corrosion and is well-suited to ground support and interior applications, where cadmium restrictions apply.

Zinc plating also provides:

- Corrosion protection for steel housings and brackets.

- A safer alternative to cadmium for non-critical assemblies.

- Higher cost efficiency for high-volume components.

- Potential for enhancement with chromate topcoats to increase durability.

Understanding AS 9100 and Its Role in Aerospace Metal Finishing

AS 9100 is an international quality management standard for aviation, space, and defense manufacturing. Certification to this standard ensures that strict process controls are implemented and followed for risk management and continuous improvement. Core requirements include:

- Meeting OEM and Tier 1 contractor requirements.

- Maintaining full traceability of every part processed.

- Ensuring process repeatability and documentation.

- Supporting auditing, compliance, and customer satisfaction.

The Importance of NADCAP Accreditation in Aerospace Finishing

NADCAP accreditation is the gold standard for aerospace component finishing. Managed by the Performance Review Institute, it verifies that special process providers, including electroplating companies, meet industry-specific technical requirements. These requirements include:

- Validating technical capability and process control.

- Reduced supplier risks in aerospace programs.

- Alignment with prime contractor specifications.

- A commitment to continuous quality improvement.

Trust New Method Plating for Precision Aerospace Metal Finishing

From cadmium and chem film to nickel and zinc plating, New Method Plating provides expert finishing backed by extensive industry knowledge. We are AS 9100-certified and hold NADCAP accreditation.

Contact us to learn more about our capabilities, or request a quote to discuss your next aerospace plating project.