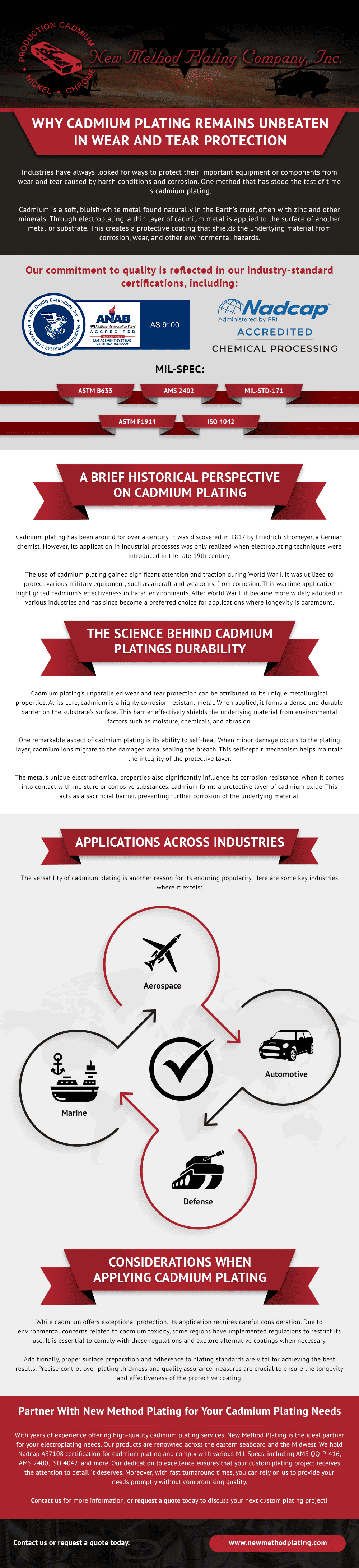

Beyond the Surface: Exploring the Science and Benefits of Nadcap Cadmium Plating for Wear Protection

Comments Off on Beyond the Surface: Exploring the Science and Benefits of Nadcap Cadmium Plating for Wear ProtectionNadcap cadmium plating is the process of applying a layer of cadmium onto a metal substrate to enhance its corrosion resistance. This plating method is certified by Nadcap, an accreditation program for defense and aerospace industries. It verifies that the plating process adheres to specific technical requirements and industry best practices established by regulatory bodies.

This article will examine the key characteristics of this Nadcap cadmium plating, including its advantages and the quality control measures enforced by Nadcap certification.

The Science Behind Nadcap Metal Plating

Nadcap plating involves a scientifically precise process of depositing a metal layer onto a substrate. This plating technique relies on electroplating, where an electric current reduces dissolved metal cations to form a coherent coating. In the case of cadmium plating, the substrate is the cathode, whereas cadmium ions act as the source of the plating material.

The science behind Nadcap cadmium plating includes material properties and surface chemistry considerations. Cadmium a relatively rare transition metal offers excellent corrosion resistance that is ideal in harsh environments such as aerospace applications. Its ability to form a stable oxide layer further enhances its protective properties.

Benefits of Nadcap Cadmium Plating

Here are the key advantages of this specialized cadmium plating technique:

Corrosion Resistance

Cadmium forms a protective oxide layer on the substrate’s surface, shielding it from corrosion caused by moisture, salt, and other corrosive agents. This makes it particularly valuable in aerospace and defense applications where components are exposed to extreme conditions.

Durability

Cadmium plating offers a durable coating that can withstand mechanical stress, abrasion, and temperature variations. This durability ensures the longevity of parts and components, reducing the need for frequent maintenance and replacement.

Lubricity

The lubricating effect helps minimize frictional losses and prevents seizing or galling of components. This property is highly advantageous in manufacturing fasteners, bearings, and gears, where smooth operation and extended service life are essential.

Conformity to Standards

Nadcap certification ensures that cadmium plating processes adhere to strict industry standards and specifications. This conformity guarantees consistent quality and performance, meeting the rigorous requirements of aerospace, defense, and other high-tech industries.

Cost-Effectiveness

While cadmium plating may involve higher initial costs than other coatings, its long-term benefits often outweigh the initial investment. It provides significant savings over time, making it a cost-effective solution for critical applications.

Quality Control Measures for Nadcap Cadmium Plating

Implementing the following measures ensures that Nadcap plating meets the stringent requirements of aerospace, defense, and other high-tech industries:

- Process validation: Before the initial production, it is essential to validate the process to ensure it meets the required parameters for adhesion and corrosion resistance.

- Documentation: Thorough documentation is conducted throughout the operation. This comprises thorough techniques, specs, and records of plating parameters.

- Quality inspections: These inspections may involve visual examination, thickness measurements using X-ray fluorescence (XRF) or eddy current testing, and adhesion tests such as ASTM B571.

- Calibration of equipment: Plating baths, thickness gauges, and voltage meters are all calibrated regularly to ensure accuracy and reliability.

- Audits and reviews: These are conducted internally by the company’s quality management team or externally by Nadcap auditors to assess the effectiveness of quality control measures.

Choose New Method Plating for High-Quality Plating Solutions

At New Method Plating, we pride ourselves on our unwavering commitment to delivering high-quality plating services! With nearly 80 years of experience, we have established ourselves as an industry leader trusted by aerospace manufacturers. We also invest in state-of-the-art technology and employ skilled professionals to deliver superior results.

Contact us or request a quote now!