Mastering Clear Zinc: The Definitive Guide to Modern Corrosion Protection

Clear zinc, scientifically known as zinc chromate, consists of zinc particles and chromate compounds. Zinc acts as a sacrificial anode, corroding instead of the base metal, while chromate compounds enhance corrosion resistance by forming a protective barrier. This synergistic combination provides effective and durable protection against rust and degradation.

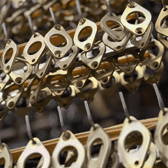

At New Method Plating, we have led the industry in delivering top-notch zinc electroplating services since 1931. Our clear zinc plating process suits various components used across sectors, ensuring durability in diverse operating conditions from military and automotive to construction and manufacturing.

Key Advantages of Clear Zinc Coating

Clear zinc offers several advantages over traditional corrosion protection methods, making it a preferred choice in various industries. Here are some key benefits:

- Extended durability: Clear zinc provides prolonged protection to metal surfaces, reducing the frequency of maintenance and the need for replacements.

- Superior adhesion: The coating exhibits excellent adhesion to metal surfaces, ensuring a strong and lasting protective layer. This robust adhesion helps maintain the integrity of the coating even under challenging environmental conditions.

- Transparency: Unlike traditional coatings that may alter the appearance of metal surfaces, clear zinc maintains a transparent or nearly colorless finish. This allows the natural aesthetic of the metal to remain visible, making it suitable for applications where visual appeal is important.

- Reduced maintenance costs: Clear zinc’s extended durability results in lower maintenance costs over time, making it a more cost-efficient choice than traditional methods that may require frequent interventions.

- Sacrificial protection: In the event of damage or wear, the zinc corrodes preferentially instead of the base metal. This provides an additional layer of protection against rust and degradation.

- Reduced environmental impact: The composition and application methods of clear zinc align with sustainable practices, reducing the environmental impact associated with corrosion protection processes.

- Versatility: Clear zinc can be applied to various metal components and structures, adapting to diverse corrosion challenges.

Step-By-Step Guide to Clear Zinc Application

Clear zinc requires a meticulous application process to ensure its effectiveness. Here are the steps involved:

1. Surface Preparation

Before applying clear zinc, thorough surface preparation is crucial for proper adhesion and long-lasting protection. Experts will remove dirt, grease, or contaminants from the metal surface using appropriate cleaning agents.

Depending on the condition of the metal, techniques such as sanding or abrasive blasting may be necessary to create a clean surface. In addition, applying a primer compatible with clear zinc can sometimes enhance adhesion and overall performance.

2. Coating Application

Airless spray application is a common method for clear zinc coating. It uses specialized spraying equipment to achieve an even and controlled coating thickness. A brush or roller application may be necessary for smaller or more detailed areas. It ensures an even application to metal components.

Experts follow a recommended application thickness guideline. This prevents inconsistencies that cause uneven drying or low protection, reducing effectiveness.

3. Drying and Curing

After application, the coated metal is left to dry. Factors influencing its drying time may include coating thickness, ventilation, and environmental conditions. Proper drying ensures the clear zinc coating adheres uniformly and achieves the desired protective properties. Some coatings may also require curing to reach maximum hardness and durability.

4. Quality Control

Lastly, technicians will inspect the coated surfaces for any signs of uneven application, bubbles, or other imperfections. Regular quality control measures help ensure the effectiveness of the clear zinc application.

Clear Zinc Application Across Industries

Here are some sectors where clear zinc coating reigns supreme as a go-to solution for safeguarding metal structures:

Marine Industry

Clear zinc is highly valued in the marine sector because it can resist corrosion in harsh saltwater environments. It is commonly used for protecting metal components on boats, including fasteners, hulls, and other exposed parts. It is also applied to metal structures such as docks, piers, and offshore platforms to prevent corrosion from saltwater exposure.

Automotive Sector

The automotive industry uses clear zinc coating to protect various metal components. This includes coating bolts, nuts, and other fasteners, especially undercarriage components. It is also applied to chassis parts for cars and trucks to extend their lifespan and enhance corrosion resistance.

Industrial Applications

Metal structures in industrial settings are often exposed to challenging conditions. Clear zinc is commonly used to protect metal machinery and equipment from corrosive elements in manufacturing facilities. Furthermore, it can be applied to storage tanks and containers to prevent rusting caused by the storage of chemicals and other substances.

Construction and Infrastructure

Clear zinc is an ideal choice for corrosion protection in the construction industry. It is applied to structural steel elements in buildings, bridges, and infrastructure projects to enhance longevity. In particular, it is used in exterior components such as metal railings and fences to protect against harsh weather.

Aerospace and Aviation

In the aerospace sector, clear zinc protects vital aircraft and related equipment components, including fasteners, brakes, avionics systems, and turbine blades. This ensures the safety and reliability of aviation systems.

Oil and Gas Industry

Metal structures in the oil and gas sector face exposure to corrosive chemicals and substances. Clear zinc is commonly applied to pipelines, drilling equipment, and constructions. This ensures safe and reliable exploration and extraction operations.

Latest Advancements in Clear Zinc Technology

In the ever-evolving landscape of corrosion protection, clear zinc continues to advance, incorporating innovative technologies to enhance its effectiveness. Here are some of the latest advancements shaping the future of its applications:

Nano Coating Technology

Harnessing the power of nanotechnology, some clear zinc formulations now feature nano-sized zinc particles. These offer increased surface coverage and penetration, creating an even more robust protective barrier against corrosion.

Self-Healing Formulations

Emerging self-healing clear zinc coatings are equipped with the ability to mend minor scratches or abrasions on their own. This innovation is achieved by incorporating microcapsules containing corrosion-inhibiting agents within the coating. When damage occurs, these microcapsules rupture, releasing the healing agents to repair and reinforce the protective layer.

Advanced Application Techniques

Modern application methods are introducing automated and precision-controlled systems. Robotic application technology ensures consistent coating thickness and uniform coverage, reducing the margin for error associated with manual application. This advancement not only improves the efficiency of the application process but also enhances the overall performance of coatings.

Environmentally Friendly Formulations

In response to growing environmental concerns, the latest advancements in clear zinc include formulations with reduced environmental impact. Manufacturers are developing coatings that meet or exceed stringent environmental regulations, ensuring they align with sustainability goals.

Enhanced UV Resistance

Clear zinc coatings are now designed to offer improved ultraviolet (UV) radiation resistance. This advancement is particularly beneficial in outdoor applications where prolonged exposure to sunlight can degrade conventional coatings. Enhanced UV resistance ensures that clear zinc maintains its protective qualities over an extended period, even in challenging weather conditions.

New Method Plating: Transform Your Metal Components With Our Superior Clear Zinc Plating

Discover the unparalleled benefits of clear zinc plating for your metal parts with New Method Plating! We have been an industry leader since 1931, specializing in high-quality zinc electroplating services for components used in moderate to severe environments. Moreover, we proudly hold certifications like ISO 9001:2015, AS9100, Nadcap AS7108, and Mil-Specs such as ASTM B633, AMS 2402, MIL-STD-171, ASTM F1914, and ISO 4042. This ensures that we provide only the best products with quick turnaround.

Contact us or request a quote today to experience the unmatched quality of our clear zinc plating services!

See Our Portfolio Gallery

© 2025 New Method Plating Company, Inc. All Rights Reserved | Site Created by Thomas Marketing Services

Comments are closed